| Max cutting lenght | 2000 mm |

|---|---|

| Size tile for diagonal cutting | 1410×1410 mm |

| Max cutting thickness | 85 mm |

| Max cutting depth with 2 RUNS | 135 mm |

| Max cutting depth for 45° (jolly) cut | 60 mm |

| Diamond blade diameter | 300 mm |

| Machine's dimension in stock | 72x275x100 mm |

| Tool hole | 25,4 mm |

| Power engine | 3Hp/2,2Kw, 9A |

| Rotation speed | 2800rpm |

| Amperometric protection | 13 A |

| Engine type | SINGLE-PHASE 230V~50Hz |

| Side bench dimesion | 2055×625 mm |

| Machine's dimension | 2720x770x H1280 mm |

| Weight | 99 kg |

| Thermic protection | 160°C |

| Water pump | S3 |

| Water tank capacity | Min.40/ Max.60 liters |

| Side tile support | Optional |

| Long slot for side tile support | Optional |

| Cutting progress system | Standard |

| Side banch with rollers | Optional |

| Extension side bench | Optional |

| Wheels | Optional |

| Fence | Standard |

| Laser instrument | Optional |

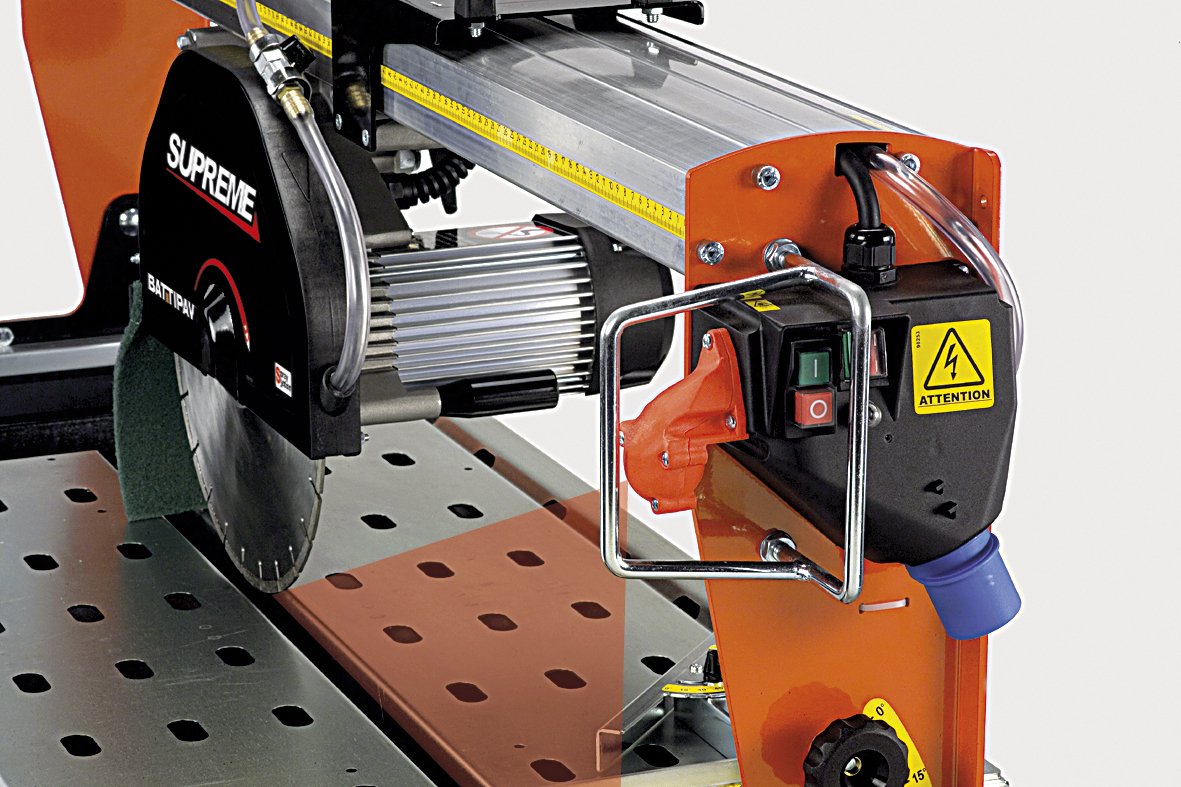

SUPREME is a bridge saw ideal for cutting natural stones, granite and marble slabs.

It makes cuts moving forward manually the engine group.

It is built to work with diamond disk Ø300 mm.

Laser instrument and kit wheels are supplied standard or as optionals.

Equipped with:

– Single phase engine 230V 50Hz 3Hp/2,2Kw with thermal and amperometrical protection

– Switch with release coil

– Overheat protection with manual reset

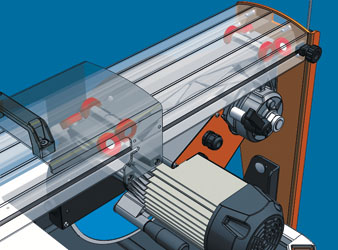

– Sliding cutting head and tilting engine

– Cutting progress system with hand wheel

– Adjustable legs

– Adjustable goniometer fence

– Water recycling pump type S3

Disk Ø 300 not included.